Your neighbor’s putting green looked perfect for three seasons. By the fourth, the fibers had faded to a sickly gray-green, the backing had cracked at the seams, and the whole thing smelled faintly of mildew. He’d bought quality turf—just the wrong turf for Phoenix.

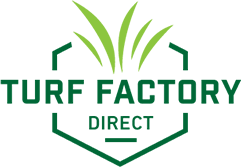

The best outdoor putting green turf is a climate-specific formula built on three matches: UV and heat intensity determine your fiber type, rainfall and humidity dictate drainage and infill requirements, and freeze-thaw cycles demand specific backing flexibility. Nail these three, and your artificial putting green for backyard practice performs for a decade or more. Miss one, and you’re fighting your environment instead of sinking putts.

This guide walks through each specification, explains why it matters for your region, and connects the technical details to real-world performance. Whether you’re installing in desert sun, Gulf Coast humidity, upper Midwest winters, or somewhere in between, you’ll finish knowing exactly what to prioritize.

Key Takeaways

- Climate determines turf selection: The three critical matches are fiber type to UV/heat exposure, drainage and infill to precipitation/humidity, and backing flexibility to freeze-thaw cycles.

- Nylon dominates hot, sunny climates: Its molecular structure—specifically amide linkages that absorb UV light—provides superior resistance to degradation and maintains fiber integrity for 10+ years with proper maintenance.

- Drainage is non-negotiable in wet regions: Quality putting green systems handle at least 30 inches of water per hour. Inadequate drainage is among the most common failure modes.

- Flexible backing prevents cold-climate failures: Rigid materials develop micro-cracks through repeated freeze-thaw cycles. Rubber backing absorbs expansion without structural damage.

- Antimicrobial infill prevents mold when humidity exceeds 60%: The EPA identifies this threshold as the point where mold growth becomes likely.

- Proper subbase preparation matters more than turf selection: A foundation of 2–4 inches of gravel plus 6–8 inches of compacted aggregate ensures long-term performance.

- Surface temperatures on synthetic turf run 35–55°F hotter than natural grass: Light-colored infill can reduce temperatures measurably.

The 60-Second Climate Match: Quick Reference Guide

| Your Climate Type | Priority Specs | Recommended Features | TFD Product Fit |

| Hot & Sunny (Desert/Southwest) |

UV resistance, heat dissipation | Nylon fiber, UV stabilization, light-colored infill | TFD Birdie Putt Elite, TFD Nylon Putt Extreme |

| Hot & Humid (Southeast/Gulf) |

UV resistance + drainage + antimicrobial | Nylon fiber, permeable backing, antimicrobial infill | TFD Nylon Putt Extreme + Antimicrobial Sand Infill |

| Cold & Snowy (Northeast/Midwest) |

Freeze-thaw flexibility, fiber resilience | Flexible rubber backing, shorter pile | TFD Putting Elite |

| Wet & Rainy (Pacific Northwest) |

Superior drainage, mold prevention | Top-drain or side-drain systems, antimicrobial infill | TFD Birdie Putt Elite + Antimicrobial Sand Infill |

| Moderate/Transitional | Balanced performance | Polyethylene or nylon, standard drainage | TFD Poly Putt, TFD Two-Tone Putt |

That’s the shortcut. The sections below explain the why—and help you fine-tune for your exact conditions.

Understanding Your Climate’s Demands on Outdoor Putting Green Turf

The quick-match table gets you started. Now let’s dial in the details.

Identifying Your Climate Profile

Pull up your city’s weather data. These five numbers tell you which specifications to prioritize:

- Temperature: Summer highs consistently above 90°F put you in “hot climate” territory. Regular triple-digit days make UV stabilization non-negotiable.

- Rainfall: More than 40 inches annually means drainage is your primary specification. But frequency matters more than totals—regions with heavy afternoon downpours need faster drainage than areas with gentle, steady rain.

- Freeze-thaw cycles: Count how often temperatures cross 32°F, not just how cold it gets. Fifty-plus crossings annually demand flexible backing. Regions with sustained deep freezes are actually gentler on turf than areas where temperatures bounce above and below freezing constantly.

- UV index: Average readings of 7+ during peak months make UV-resistant putting green turf critical. Southern latitude and high altitude compound the effect.

- Humidity: Sustained levels above 60% combined with warmth create mold-friendly conditions. Shaded installations in humid climates face higher risk than sunny ones—less natural UV to keep organic growth in check.

How Climate Affects Turf Performance

Four failure modes. Four reasons specifications matter.

- UV degradation starts with color loss—that faded, grayish cast that screams “cheap turf” even when the turf wasn’t cheap. Then fibers turn brittle. Snap instead of bend. Nylon’s molecular structure absorbs UV light and converts it to heat, providing inherent resistance to this breakdown. Quality UV-stabilized turf handles thousands of hours of direct exposure; budget alternatives show wear within two or three seasons.

- Heat stress works below the surface. Backing materials soften, shift, lose their grip on fiber tufts. Seams separate. Infill migrates into low spots. Penn State’s Center for Sports Surface Research shows synthetic turf surfaces typically run 35–55°F hotter than natural grass. Light-colored silica infill reflects more sunlight than darker alternatives, reducing surface temperature measurably—the difference between comfortable barefoot practice and waiting until evening.

- Moisture accumulation announces itself unmistakably: that swamp smell drifting across your patio. Poor drainage creates standing water. Standing water breeds mold, deteriorates backing, and turns your investment into an eyesore. In humid climates, moisture doesn’t just come from rain—ambient humidity keeps surfaces damp even on clear days.

- Freeze-thaw stress is simple physics. Water expands when frozen. Rigid backing materials resist that expansion, developing micro-cracks that accumulate through dozens, then hundreds, of cycles. Eventually, visible damage. Seam separation. Flexible rubber backing absorbs the expansion and contraction without complaint.

Fiber Types: Matching Material to Your Weather

The fiber is what you see, touch, and putt on. It’s also the first line of defense against sun and heat.

Nylon Putting Green Turf: The Heat and UV Champion

Many professional practice facilities feature nylon putting surfaces. There’s a reason.

Nylon’s dense molecular structure shrugs off UV exposure that would degrade other materials. It handles heat without softening. And it has memory—compress it under foot traffic, and it bounces back rather than matting flat over time. The actual synthetic turf material in quality putting greens is typically made of nylon or polypropylene, with nylon offering superior performance in demanding conditions.

- Climate fit: Hot, sunny environments. Desert Southwest. Southern California. Texas. Anywhere UV index regularly hits 8+ and summer temperatures push past 100°F.

- On the green: Nylon delivers the firmest, fastest surface. Ball reaction stays consistent year after year because the fiber maintains its structure. This is why serious practice facilities specify nylon.

- The trade-off: Firmness means less forgiveness on chip shots. And nylon costs more upfront. In harsh sun, that investment returns through dramatically longer lifespan. In mild climates, you’re paying for durability you may not need.

TFD Nylon Putt Extreme and TFD Two-Tone Putt deliver UV-resistant nylon engineered for demanding conditions.

Polyethylene Turf: Soft Touch for Moderate Climates

Polyethylene feels different underfoot. Softer. Slightly more grass-like in appearance. Modern UV-stabilized versions perform well where extreme heat isn’t a daily factor.

- Climate fit: Transitional zones. Mid-Atlantic. Pacific coastal areas with marine influence. Four-season northern regions without brutal UV exposure.

- On the green: Softer landing for chip shots. Slightly slower roll—which some recreational players actually prefer. More natural appearance if aesthetics matter as much as performance.

- The trade-off: Extreme heat can accelerate wear. If summer highs regularly exceed 95°F under intense sun, nylon likely delivers better long-term value. The nylon vs polyethylene putting green choice ultimately comes down to climate demands—heat tolerance versus softer feel.

TFD Poly Putt pairs polyethylene fibers with a 1-inch pile height suited to family use and casual practice.

Polypropylene: Budget Considerations and Climate Limitations

Polypropylene costs less. It shows.

Acceptable for mild climates with limited sun exposure. Shaded installations. Covered patios. Budget-conscious projects where the green is a nice-to-have rather than a serious practice tool.

The reality: Significant direct sun or temperature extremes—hot or cold—shorten polypropylene’s lifespan enough that the lower upfront cost becomes a false economy.

Fiber Comparison at a Glance

| Fiber Type | UV Resistance | Heat Tolerance | Feel | Durability | Climate Fit |

| Nylon | Excellent | Excellent | Firm, fast | Highest | Hot, sunny, high-UV |

| Polyethylene | Good | Moderate | Soft, natural | Good | Moderate, transitional |

| Polypropylene | Fair | Low | Variable | Lower | Mild, shaded, budget |

Drainage and Backing Systems for Different Climates

What happens beneath your turf determines whether it thrives or fails. Drainage and backing aren’t glamorous specifications, but they’re often decisive ones.

Permeable vs. Non-Permeable Backing

Permeable backing lets water pass through the turf surface and backing into the subbase below. Essentially anywhere rain actually falls.

Non-permeable options exist for extremely arid environments where retaining trace moisture might benefit the installation. This describes a small minority of projects.

The benchmark that matters: A quality putting green drainage system handles at least 30 inches per hour—the minimum water permeability standard recognized by municipal codes for artificial turf installations. In heavy-rainfall regions—Pacific Northwest, Gulf Coast, Southeast—look for rates exceeding this threshold. Inadequate drainage is among the most common failure modes in wet climates.

Top Drainage vs. Side Drainage

Top drainage moves water straight through perforations in the turf face, down through backing, into the subbase. Handles steady rainfall efficiently. Keeps the surface playable during light drizzle.

Side drainage channels water laterally to edges. Handles heavy downpours better than top-only systems. Reduces surface pooling during intense storms.

Match the system to your rain patterns. Frequent heavy downpours? Side drainage systems like TFD Birdie Putt Elite handle the volume. Steady, moderate rainfall? Top-drainage designs like TFD Nylon Putt Extreme work efficiently.

Backing Materials and Freeze-Thaw Survival

Picture a bottle of water in your freezer. It expands as it freezes—sometimes enough to crack the container. Now picture that process happening inside your turf’s backing material. Fifty times a year. A hundred times.

Rigid backings resist the expansion. Micro-fractures form. Accumulate. Eventually become visible cracks and seam failures. Research confirms that freeze-thaw cycling causes progressive micro-cracking and structural degradation in rigid materials.

Natural rubber backing stays flexible even at low temperatures. It absorbs freeze-thaw cycles without structural damage. TFD Putting Elite uses this technology specifically for cold-climate resilience.

Urethane backing offers excellent durability and dimensional stability in moderate climates. TFD Poly Putt pairs urethane backing with softer polyethylene fibers for transitional environments.

If you experience 50+ freeze-thaw cycles annually, putting green turf for cold weather demands one thing above all else: backing flexibility. It trumps almost every other specification.

Infill Selection for Climate-Specific Protection

Infill is the material brushed into turf fibers after installation. It affects ball roll, fiber support, and climate performance more than most buyers expect.

Sand Infill: Weight, Stability, Temperature

Silica sand serves triple duty: it anchors the turf, supports fibers in their upright position, and influences surface temperature through thermal mass.

In hot climates, color matters. Light-colored silica reflects more sunlight than dark rubber infill, reducing surface temperature measurably. Not a marketing claim—basic physics. In desert installations, this affects both comfort and turf longevity.

Proper application runs 1-2 pounds per square foot, varying with pile height and manufacturer specs. Even distribution is essential; uneven infill creates inconsistent ball roll.

Antimicrobial Turf Infill: When Moisture Won’t Leave

Warm plus wet equals mold-friendly. The EPA recommends keeping relative humidity below 60% to prevent mold growth. If humidity regularly exceeds this threshold and annual rainfall tops 40 inches, antimicrobial turf infill moves from optional upgrade to practical necessity.

TFD Putting Green Silica Sand Infill includes antimicrobial treatment that prevents organic growth within the infill layer. Particularly important for family installations where children or pets use the green.

Essential for:

- Gulf Coast and Southeast installations

- Pacific Northwest with limited sun

- Shaded greens in any humid climate

- Installations near pools, ponds, or water features

Standard infill suffices in:

- Desert and arid climates

- Full-sun installations with good airflow

- Regions with dry summers

Putting Green Pile Height and Playability Across Climate Zones

Pile height—fiber length from backing to tip—affects both performance characteristics and, to a lesser degree, climate resilience.

Shorter Pile for Hot, Dry Climates

Shorter fibers (7/16″ to 1/2″) roll faster, simulate competitive conditions, and retain slightly less heat than longer piles simply because there’s less fiber mass absorbing and radiating warmth.

On the stimpmeter: A standard nylon surface typically reads 11 feet or less—comparable to well-maintained private club greens. Sand-filled nylon systems can reach close to 13 feet for those seeking faster conditions. This speed demands precise stroke mechanics and provides serious practice conditions.

TFD Putting Elite offers 7/16″ pile height for players chasing quality speed.

Longer Pile for Versatility and Forgiveness

Longer fibers (3/4″ to 1″) slow the ball slightly and create a more forgiving surface. Better suited to mixed-use installations where serious players, casual family members, and children share the green.

On the stimpmeter: A 1″ pile typically reads 8-9—faster than most public courses but more forgiving than competitive setups.

TFD Poly Putt features 1″ pile height, balancing playability with accessibility.

Pile Height Quick Reference

| Pile Height | Stimp Range | Character | Best For |

| 7/16″ – 1/2″ | 10-11 | Fast, demanding | Serious practice |

| 5/8″ – 3/4″ | 9-10 | Medium, versatile | All-around use |

| 7/8″ – 1″ | 8-9 | Forgiving | Families, casual play |

Synthetic Putting Green Installation Considerations by Climate Region

Proper installation prevents climate-related failures that no turf specification can overcome. What’s beneath the surface matters.

Subbase Preparation for Wet Climates

The turf drains water to the subbase. The subbase moves water away from the installation. Skip proper subbase work, and even the best-draining turf becomes a retention pond.

Wet climate specifications:

- After clearing and leveling the area, install a gravel base of 2–4 inches, then add 6–8 inches of compacted aggregate to form the foundation.

- 1-2% slope directing water away from structures (building codes require a minimum 2% slope for impervious surfaces).

- Landscape fabric between native soil and aggregate preventing migration

- Edge containment that doesn’t dam water flow

Most drainage failures in wet climates trace back to subbase shortcuts, not turf limitations.

Heat Management for Desert Installations

Orientation and shade integration affect daily usability in hot climates.

Practical considerations:

- North-south orientation reduces the most intense midday sun exposure.

- Afternoon shade from structures or landscaping meaningfully lowers surface temperature.

- Light-colored infill and borders reduce heat absorption.

- Adjacent hardscape radiates heat onto turf; separation or shading helps.

These aren’t requirements. They’re the difference between a green you use all summer and one you avoid from noon to evening.

Professional vs. DIY: Climate as a Factor

Climate complexity should influence your installation decision.

DIY-friendly situations:

- Moderate climates without drainage extremes

- Flat or simply graded sites

- Rectangular layouts

- Existing adequate drainage

Professional installation adds value when:

- Drainage requirements are complex.

- Significant grading or soil work is needed.

- The green is large or irregular.

- Freeze-thaw concerns demand precise seam work.

- Integration with existing hardscape is involved.

The turf is the investment. Installation determines whether that investment performs.

Climate-Based Maintenance: Year-Round Expectations

Every putting surface needs some attention. Climate determines what kind and how often—but nothing approaching natural grass demands.

Hot Climate Maintenance

- Weekly: Light evening rinse removes dust and cools the surface for morning practice.

- Monthly: Redistribute infill with a stiff brush; inspect for fiber flattening or early UV wear.

- Quarterly: Deep clean with turf-safe solution; check seams and edges.

Watch for infill migration and fiber compression—the two primary hot-climate wear patterns.

Wet and Humid Climate Maintenance

- Weekly: Remove organic debris—leaves and plant matter trap moisture and invite mold.

- Monthly: Inspect drainage; check for slow-draining areas or standing water; apply antimicrobial treatment if not using treated infill.

- Seasonally: Deep clean; examine backing for moisture-related deterioration.

Priority one is keeping organic matter off the surface. Everything else follows from that.

Cold Climate Maintenance

- As needed: Clear snow with plastic shovels or leaf blowers—never metal tools.

- Spring: Thorough inspection for freeze-thaw damage; check every seam; brush fibers upright after winter compression.

- Fall: Clear debris before freeze; verify drainage is clear; consider a deep clean before winter sets in.

The critical rule: no metal tools on your turf. Ever. One pass with a steel shovel can damage fibers you’ll see every time you putt.

Making Your Decision: Climate-First Selection

You understand the specifications now. Here’s how to prioritize them for your environment.

Specification Priority by Climate

Hot & Sunny — Priority Stack:

- UV-stabilized nylon fiber (non-negotiable)

- Light-colored infill

- Dimensionally stable backing

- Drainage (lower priority in arid regions)

Hot & Humid — Priority Stack:

- UV-stabilized nylon fiber

- High-drainage permeable backing

- Antimicrobial infill

- Professional subbase preparation

Cold — Priority Stack:

- Flexible rubber backing (non-negotiable)

- Resilient fiber (nylon or quality polyethylene)

- Professional seam installation

- Drainage (moderate priority)

Wet — Priority Stack:

- High-drainage backing system

- Antimicrobial infill

- Proper subbase preparation

- UV resistance (moderate unless also sunny)

Budget Alignment

Climate tells you where to invest and where to save.

Premium features that pay back:

- UV stabilization in hot climates (directly extends lifespan)

- Flexible backing in cold climates (prevents structural failure)

- Antimicrobial infill in humid climates (prevents problems you don’t want)

- Professional installation for complex drainage

Mid-tier options that often suffice:

- Fiber type in mild, shaded climates

- Standard infill in dry climates

- Basic backing in regions without freeze-thaw cycles

The most expensive option isn’t automatically the best choice. The best choice matches specifications to demands. Sometimes that’s premium. Sometimes it isn’t.

Ready to explore options matched to your climate? Browse our complete putting green turf selection with your priorities clear.

Your Climate-Matched Putting Green Starts Here

There is no “best” putting green turf. There’s only the best turf for your climate—and now you know how to find it.

Three matches determine success:

- Fiber type matched to UV and heat exposure

- Drainage and infill matched to precipitation and humidity

- Backing flexibility matched to freeze-thaw demands

Nylon for intense sun. Polyethylene for moderate climates. Skip polypropylene anywhere weather gets serious.

Drainage starts in the subbase—2–4 inches of gravel plus 6–8 inches of compacted aggregate. The turf only moves water as fast as the system beneath it can handle.

Flexible backing in cold climates is non-negotiable. Rigid materials don’t survive what winter does.

Antimicrobial infill in humid regions prevents problems you’d rather not describe to guests.

Synthetic putting greens should deliver a lifespan of 10 years or more with proper construction and maintenance. Get the matches right, and you’re stepping onto a green that performs season after season—true roll, consistent speed, no surprises. The investment pays back every time you practice without checking the weather first.

Explore climate-matched putting green options and find the specifications that fit your environment.